Power Up initiative by Festo promotes automation in food processing

Power Up initiative by Festo promotes automation in food processing

November 8, 2023 REDWIRE is news you can use from leading suppliers. Powered by FRASERS.

Posted by Festo Inc

Innovate today for a new tomorrow For nearly a hundred years Festo has provided proven Industry Leadership, Super... Read more

Subscribe

Free REDWIRE e-newsletter

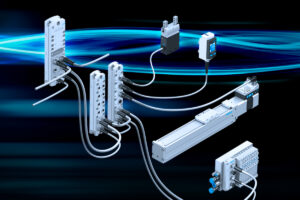

Festo’s Power Up offers one-stop shopping for complete electric-automation solutions, including advanced distributed and decentralized I/O, to transform food and beverage machine building.

Festo Canada is seeking to transform machine building in the food-processing sector with electric automation through its Festo Power Up initiative. By spurring the efficient adoption of electric automation in this industry, the manufacturer aims to support development of the next generation of compact, flexible, energy-efficient, and data-rich equipment.

Machine builders in food processing access a one-stop shop of high-quality, cost-competitive automation products through the Power Up initiative.

Supported by three pillars

Power Up is supported by three pillars: products, productivity tools, and automation platform. With Festo’s design and commissioning productivity tools, customers lower engineering overhead and bring products to market more quickly. In addition, Festo recently launched a remote, decentralized input/output (I/O) platform that reduces integration expenses while augmenting the ability of equipment manufacturers to add capabilities easily and cost-efficiently to machines and cells.

Over the last 10 years, Festo has expanded its lineup of electric-automation solutions with such options as I/O systems and controllers, pre-assembled and tested handling systems, and the Simplified Motion Series of low-cost linear and rotary axes with integrated drive, motor, and IO-Link. Also available are mechanical systems, including spindle and toothed belt axes and mini slides, ball screw and cantilever linear actuators, and parallel grippers.

Both mechanical and electronic components in Festo’s electric automation interoperate, assemble quickly and easily, and reduce the risks of integration. The company offers online productivity tools – Electric Motion Sizing and Handling Guide Online – that allow customers to design and order one-, two-, and three-axis systems in minutes; design engineers just enter application parameters, with no programming required. Next, the commissioning files are compiled automatically and ready for download to the PC-based Festo Automation Suite software. This automation platform is compatible with EtherNET/IP, EtherCAT, PROFIBUS, and Modbus communication protocols.

With Power Up, engineers, maintenance staff, and technicians have only one unified system to learn, rather than several. This reduces inventory needs, and using one supplier’s products makes field support simpler. For easy reference and reordering, Festo assigns a unique part number to every electric-automation assembly, and that number is linked to a complete parts list.

To learn more, contact Festo.

Share

Posted by Festo Inc

Innovate today for a new tomorrow For nearly a hundred years Festo has provided proven Industry Leadership, Super... Read more